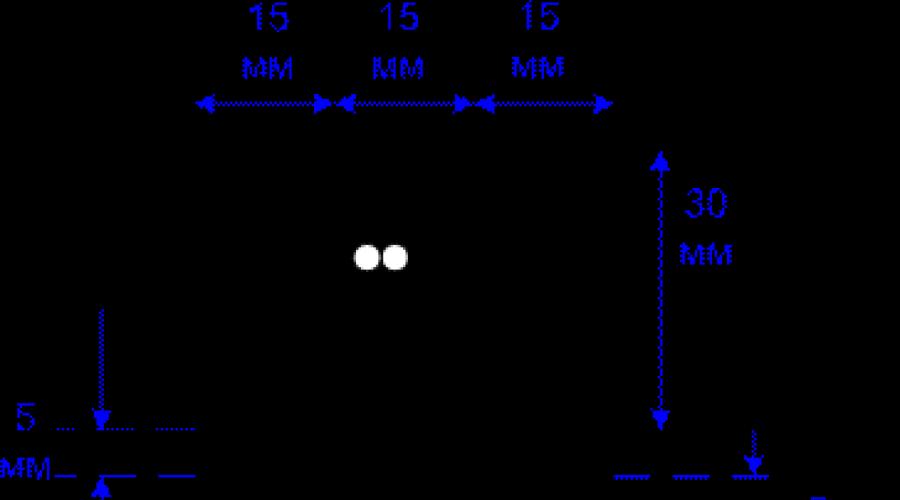

Functional diagram of block placement according to the station plan. Functional block layout diagram Functional block layout diagram according to the station plan

Read also

Send your good work in the knowledge base is simple. Use the form below

Students, graduate students, young scientists who use the knowledge base in their studies and work will be very grateful to you.

Posted on http://www.allbest.ru

Introduction

1. Operational part

1.1 Characteristics of the station

1.2 Purpose of the centralization system

2. Technical part

2.1 Single-line plan of the station with the calculation of the ordinates of the arrows and signals

2.2 Signaling of station traffic lights

2.3 Selecting the type of track circuits

2.4 Two-line station plan

2.5 Station routing

2.6 Functional block layout

2.7 Arrow control scheme

2.8 EC cable networks

3. Technological part

3.1 Checking the tightness of pressing the point to the frame rail

4. Labor protection

4.1 Occupational safety issues during the maintenance and repair of electric switch drives

Conclusion

List of sources used

INTRODUCTION

Schemes of block route-relay centralization are mounted from separate closed blocks, in which typical circuit nodes are assembled. station arrow traffic light

The main schemes for installing, closing and opening routes are obtained by typing and interconnecting typical blocks of managed and controlled objects electrical circuits in accordance with the functional block layout, drawn up according to the track development plan. For each control and monitoring object, a block of the appropriate type is provided.

The safety of train traffic in comparison with all previous systems, the operational capabilities of the system have been expanded. A feature of ETs-I type systems is a high degree of unification of route installation and opening schemes, coding, linkages with distillation systems, crossings, train fencing devices and local control, which made it possible to create a more complete structure of the ETs system.

In the modern world, the issue of improving traffic safety is becoming more and more relevant. The railway, being a zone of increased danger, does not bypass this issue. Taking into account technical progress, an increase in the speed of movement of vehicles, means are being created to ensure the safety of train traffic, control devices at a distance (automation and telemechanics). Stations are equipped with various electrical centralizations. Block route-relay centralization (BMRTS) is one of the most progressive and meeting modern security requirements.

This system of centralization has found wide application at precinct, marshalling and intermediate stations. Approximately 70% of all equipment is located in functional blocks, which are manufactured in factories in the form of standard designs with completed installation. BMRC schemes for stations are assembled by interconnecting typesetting and executive blocks in accordance with the typology of a single-line station plan. The block construction of the EC makes it possible to speed up the design of devices, reduce the time of installation work, and improve maintainability during the operation of existing devices.

All circuit constructions, depending on the individual characteristics of the station, are mounted on contact relays placed on plug-in cabinets. These schemes include: control of guard arrows; control of oversized areas; choice of indication of the input traffic light on the main or side track, as well as with a through pass; the inclusion of various route indicators; switching on the local control of arrows, switching on the crossing signaling; control and closure of switches adjacent to the receiving and departing tracks; traffic light interdependence schemes; schemes for linking with various systems of distillation devices; coding schemes for station tracks, etc. Remote control panels with a remote display or display panels with control and monitoring devices are used as control devices.

With a block route-relay centralization system (BMRTS), route control of arrows and traffic lights is used by pressing buttons according to the “from where to where” principle. Two relay groups are used: dialing group (route dialing group) and relay executive group.

The type group serves to transmit orders for the transfer of all arrows participating in the route. It also ensures the safety of train traffic, but does not fulfill the requirements of the PTE and therefore is based on a relay of the second class of reliability of the KDR type.

The relay executive group performs route closure, traffic light opening, route opening by train, route cancellation and artificial route opening, ensures train traffic safety, fulfills the requirements of PTE for EC devices and therefore is built on the first reliability class relay of NM and KM type.

The type-setting and executive groups of the relay are used in block mounting, which can significantly reduce the amount of installation work during construction, and speed up the commissioning of centralization devices, and further improve their service conditions.

Starting from 1966, the type-setting and executive groups of the relays are used in block mounting, which makes it possible to significantly reduce the amount of installation work during construction, and speed up the commissioning of centralization devices, and further improve their service conditions.

Stacking blocks of the same size, in which up to six relays of the KDR type are installed, except for the BDSH block, which is located in the NMSh relay housing, where 20 diodes are installed, for circuit decoupling of the UK angular relay.

Executive blocks are of small type (block C), where three relays of the NM type are installed and large types (blocks PS, SP, UP, etc.), where it is possible to place up to 9 relays of the NM type, but, as a rule, one of places are occupied by resistors.

The BMRC uses a two-wire switch control circuit with a PS-220M unit (starter switch), central power and central dependencies are used, i.e. all dependencies between arrows, traffic lights and track circuits are performed at the EC post, an input traffic light control scheme with double-filament lamps is used. The control apparatus is presented in the form of a control panel with a trough-type display with route control of arrows and signals. One stage of closing and sectional opening of the route is applied. A batteryless power supply system is used, i.e. there is no working battery = 220V, but a starter battery = 24V (for starting the DGA), a control battery = 24V and communication batteries = 60V are used. The station is equipped with track circuits ~ I with a frequency of 25 Hz, with a travel relay DSSh-13A, as well as point electric drives of the SP-6M type.

In the graduation project, according to the assignment, it is necessary to equip the station with a block route-relay centralization system.

1 . OPERATIONAL PART

1.1 Characteristics of the station

The station is the area in which the turnouts are laid, connecting the station tracks and parks with each other, as well as with the main, exhaust and running tracks. The necks at a given station are arranged so that several operations can be performed simultaneously in them: receiving, sending trains and performing maneuvers.

The minimum length of the receiving-departure path of the station is 850 meters.

Type of traction: on the site - electric alternating current.

rail type: P65 on main tracks, P50 on side tracks;

track circuits: normally closed;

brand of arrows: 1/11 on the main tracks, lateral 1/9;

width between tracks: 6.5 meters between main tracks and 5.3 between other tracks;

type of traffic lights: lens with double-filament lamps on red and yellow lights;

type of electric drives: non-cut SP-6M;

switch drive control circuit: five-wire;

type of auto-blocking on the adjacent section: numeric code alternating current 50 Hz;

alarm system: three-digit;

cable brand: SPBG.

The station has 6 tracks. In this neck there are 2 dead ends, 14 arrows (of which 12 are paired).

1.2 Purpose of the centralization system

For this station, block route-relay centralization (BMRTS) is selected

This centralization system has found wide application at precinct, marshalling and intermediate stations. Approximately 70% of all equipment is located in functional blocks, which are manufactured in factories in the form of standard designs with completed installation. BMRC schemes for stations are assembled by interconnecting typesetting and executive blocks in accordance with the typology of a single-line station plan. The block construction of the EC makes it possible to speed up the design of devices, reduce the time of installation work, and improve maintainability during the operation of existing devices. As a rule, the equipment of the EC post is divided into typesetting and executive groups. Separately, control and monitoring equipment can be allocated, which is connected to outdoor equipment by means of cable cores.

Floor equipment includes: direct or alternating current switch drives, track chains and station traffic lights. It is also possible to include relay cabinets, battery wells, shunting columns and towers, track fencing devices, devices for pneumoblowing arrows, electrical heating of autoswitch contacts and other devices as objects of control and monitoring.

With the help of electrical interlocking systems, routes are set at the station, but setting the route is possible only if a number of conditions are met: the arrows included in the route must be free; there is no previously defined and unused hostile route; correctly installed running and guard arrows; route closure. After checking the fulfillment of all the above conditions, the route is considered set and the traffic light (train or shunting) is opened. To control and monitor relay-type EC devices on Russian railways, three generations of control panels, manipulator panels and remote displays are in operation:

Grooved type with the use of switching lamps with a voltage of 24 V type KM-24;

From block elements (mosaic type "Domino") using switching lamps KM-24;

From block elements (mosaic sub-blocks) using green, yellow and red LEDs.

At stations with relay-processor and microprocessor-type EC devices, personal computers with 17-21 inch monitors are used as control and monitoring devices.

To control the installation of the route, the state of the turnout and non-turnout sections of the track and the receiving and departing tracks, the burning of traffic lights, the position of the turnouts and the occupancy of the hauls, artificial opening on the control panel, the following light cells are provided.

2 . TECHNICAL PART

2.1 Single-line plan of the station with the calculation of the ordinates of the arrows and signals

The schematic plant plan is a technical document that is drawn up to determine the configuration, local conditions, construction volumes, methods of management and operation of the future plant.

The plan shows:

Track development and general configuration of the station in a single-track design, which is determined by the number and location of rail tracks and turnouts relative to each other;

Placement of insulating joints (IS);

Locations of traffic lights and their colors;

Specialization and numbering of receiving and departing tracks, arrows and traffic lights in accordance with the evenness of the neck and the chosen direction of movement;

Designation of sections of approach and removal of the stage;

Placement of the post of electrical centralization, passenger building;

Station axis;

Table of distances from the station axis to turnouts and traffic lights;

Placement of relay and battery cabinets;

Cable network route (general designation);

Guarded and unguarded crossings at the intersections of station tracks with motor roads, indicating the length of the crossing, the length of the section approaching the crossing, the estimated notification time, and the location of the control equipment;

Passage of VSL AB;

The schematic plan is the main technical document used in the construction and operation of a railway station.

Ordinate - the distance from the axis of the station to the arrow or traffic light. The calculation of ordinates is carried out using standard tables, taking into account the type of rails, brands of crosses, the layout of turnouts, the radius of the turnout curve, the width of the distance between tracks, and the design of traffic lights.

The calculation begins with determining the ordinate of the traffic light that is on the PO path with the minimum length. Path 6 is 850 meters long.

850 / 2 = 425 meters

On the ordinate of 425 meters, the output traffic light Ch6 will be located.

Further, according to the standard tables, taking into account the types of rails, brands of crosses, laying schemes for turnouts, radii of turnout curves, the width of the tracks, the design of traffic lights, the ordinates of the arrows are calculated.

C21 = 425 + 64 = 489 meters

C19 \u003d 489 + (86.6 2) \u003d 662.2 meters

C25 \u003d 662.2 - 73.7 \u003d 588.5 meters

C27 \u003d 588.5 - 18.1 \u003d 570.4 meters

C23 \u003d 588.5 + 99.8 \u003d 688.3 meters

C11 = 662.2 +18.1 = 680.3 meters

C9 \u003d 680.3 + 99.8 \u003d 780.1 meters

C15 \u003d 780.1 - 73.7 \u003d 706.4 meters

C13 \u003d 706.4 + 86.6 \u003d 792.9 meters

C17 = 792.9 - 45.9 = 747 meters

C7 \u003d 792.9 + 18.1 \u003d 811 meters

C5 \u003d 811 + 86.6 \u003d 915.7 meters

C3 = 879.6 +18.1 = 915.7 meters

C1 \u003d 915.7 + 99.8 \u003d 1015.5 meters

Based on the ordinates of the arrows, the ordinates of the remaining traffic lights are calculated.

CHII \u003d 570.4 - 64 \u003d 506.4 meters

Ch3 \u003d 747 - 55 \u003d 692 meters

Ch5 \u003d 747 - 55 \u003d 692 meters

Ch4 = 570.4 - 64 = 506.4 meters

M1 = 915.7 + 63 + 3.5 = 877.5 meters

M3 = 1015.5 + 4.3 = 1019.8 meters

M5 = 811 + 63 + 3.5 = 87.5 meters

M7 = 811 - 2.82 = 808.18 meters

M9 = 792.9 + 2.82 = 795.72 meters

M13 \u003d 706.4 + 63 + 3.5 \u003d 772.9 meters

M11 \u003d 680.3 + 62 + 3.5 \u003d 745.8 meters

M15 \u003d 588.5 + 62 + 3.5 \u003d 654 meters

M17 \u003d 489 + 63 + 3.5 \u003d 555.5 meters

M19 = 588.5 - 62 - 3.5 = 523 meters

H \u003d 988.2 + 300 \u003d 1288.2 meters

ND \u003d 1015.5 - 62 + 300 \u003d 1253.5 meters

2.2 Signaling of station traffic lights

Knowledge of traffic signaling is a prerequisite for training a specialist in the field of railway automation systems. Below is the required minimum knowledge in this area.

It must be borne in mind that in the rules, instructions and other normative sources the word "signal" is used in two meanings: as a conventional sign that transmits an order, and as a device (device) that forms this sign. It happened historically, and, nevertheless, in order to avoid confusion, the terms “signal” and “traffic light” should not be equated.

Signals in railway transport are designed to ensure safety and clear organization of train traffic and shunting work. According to the way of perception, they are divided into visible (traffic lights, disks, shields, lanterns, flags, signal indicators and signal signs) and sound (locomotive horns, hand whistles, wind horns, sirens and firecrackers). The signal is an order and is subject to unconditional execution using all possible means for this.

The main signaling devices are traffic lights. The indications of traffic lights are controlled by means of railway automation systems - AB, PA B, EC, etc. For signaling related to the movement of trains and shunting work, the following main signal colors of traffic lights are used: green, yellow, red, moon-white and blue. The procedure for the use of signal colors and the speed of passage of certain signal indications of traffic lights are established by the instruction, as well as the Instructions for the use of traffic signal signaling on railways with additions.

The signal indications of traffic lights are determined by the accepted value of the signaling system. Two-digit, three-digit and four-digit systems have found use on mainline railways.

Two-digit signaling is used at exit traffic lights at PAB. Two signals are given (Fig. 1.1):

One green light -- “The train is allowed to leave the station and proceed at the set speed; the passage to the next station (track post) is free”;

To increase the throughput of the stage during the PAB, checkpoints are arranged, which are equipped with two-digit input-output traffic lights CBP and NBP.

The most widespread is the three-digit signaling used on the road network during an accident, when three signals are the main ones (Fig. 1.2):

One green light - “Movement at the established speed is allowed; two or more block sections are free ahead”;

One yellow light - “Movement is allowed with a readiness to stop; the next traffic light is closed”;

One red light - "Stop! It is forbidden to pass the signal.

Traffic lights are divided into:

By appointment - for input, output, route, checkpoints, cover, barrage, warning, repeat, locomotive, shunting, hump; at the same time, one traffic light can combine several purposes: input and output, output and shunting, route and output, etc.;

By mode of action (automatic, semi-automatic);

According to the regulations for the procedure of prohibiting indications (absolute, stopping-permissive, conditional-permissive);

By design - on mast and dwarf, as well as mounted on bridges and consoles;

By device optical system- for lenses, spotlights and LEDs.

According to the method of signaling indications - normally burning (constantly burning, regardless of the train situation) and normally non-burning (turn on when the rolling stock enters the section in front of the traffic light and go out after the rolling stock leaves this section), non-blinking and flashing (periodically lighting up for 1 s and going out for 0.5 s).

The following traffic lights are used at the station:

input - allowing or forbidding the train to follow from the haul to the station;

weekends - allowing or forbidding the train to leave the station for the haul;

shunting - allowing or forbidding the production of maneuvers.

All traffic lights at the station are lenticular with double-filament lamps on red and yellow lights.

2.3 Selecting the type of track circuits

Two-strand two-throttle phase-sensitive rail circuits are used on the main and side receiving-departure tracks, switch and non-switch sections. Single-strand track circuits - in low-traffic areas, on secondary and access roads, due to the fact that coding them with ALS codes does not make sense due to the high level of traction current interference caused by its complete asymmetry.

In two-strand phase-sensitive rail circuits with a frequency of 25 Hz in sections with direct current electric traction, a relay of the DSSh-13A type (Appendix B) is used as a travel relay. In two-strand track circuits of this type, choke-transformers of the DT-0.6-1000M type are used and provide for the imposition of numerical ALSN code signals. For these track circuits, the standard RTs-25-ETOO-S-87 has been issued, which considers improved performance characteristics rail circuits.

At the supply end, a BOD block specially designed for such track circuits is included. This unit has two parallel connected transformers. In the circuit of the transformer T1, a protective filter L1 - C1 is included, which reduces the mutual influence of the supply circuit with a frequency of 25 Hz and the coding circuit of 50 Hz. A choke L2 is connected in series with transformer T2, which reduces the shunt effect on this 50 Hz code current transformer, capacitor C2 is connected to tune the track circuit into resonance with the 25 Hz signal current.

At the relay end, a BRK block specially designed for such track circuits is also included. In this block for coding the track circuit, a T3 transformer is installed. Similarly to the BOD block, it includes a protective filter L1 - C1 and a choke L2. Parallel to the winding of the travel relay P, a protective filter L3 - C3 is connected, tuned to a frequency resonance of 50 Hz and shunting the winding of the relay P for currents with a frequency of 50 Hz.

A short circuit in insulating joints between adjacent station track circuits is controlled by alternating instantaneous polarities at the joints by switching wires on the secondary windings of the track transformer.

The station uses AC electric traction. Therefore, normally closed phase-sensitive track circuits with a frequency of 25 Hz and choke-transformers 2DT-1-150 with a track box are used.

RC with a frequency of 25 Hz has the following advantages:

Low power consumption;

Stable operation with reduced ballast resistance;

Reliable protection against the influence of industrial frequency current 50 Hz;

Harmonic components of traction current;

Reliable phase protection against the influence of adjacent RCs at short circuit IS.

All these factors provide the necessary safety and eliminate the possibility of some failures.

1.4 Two-line station plan

A two-line station plan is drawn up on the basis of a schematic (single-line) station plan and is the main document for equipping a station with track circuits and placing electrical interlocking track equipment.

On a two-line plan of the station are shown:

Arrows and paths in a two-strand image;

Path software specialization;

SEP, traffic lights with coloring of signal lights;

Post EC;

RSH and BSh indicating the number of batteries installed in them;

Insulating joints, rail connectors;

Travel choke-transformers, branching couplings;

The main route of the cable network;

Designation of software tracks, switch and non-switch sections;

Length of ON paths;

Table of ordinates.

2.5 Station Routing

Freight transportation routing is a method of organizing car flows, in which at loading points (including on the access roads of enterprises), trains are formed from cars that pass no more than one passing technical station without processing - changing the composition. Such trains are called block trains, or routes. Block trains are classified according to the conditions of the organization, the purpose of the cars, the range of circulation, the conditions of circulation. According to the conditions of organization, trains are divided into departure trains, loaded and formed by one or more consignors on the same access track, and stepped trains, loaded by different consignors at the same station (step station) or on the tracks of several stations of a section or node (step precinct).

According to the purpose of the wagons, trains are distinguished:

Direct - formed from wagons to one unloading station with goods for one or several consignees;

In spraying - by appointment to a technical station. The wagons then follow in accordance with the plan for the formation of a spraying station;

With the appointment to the station for addressing cargo, allocated as an addressing base.

According to the range of circulation, trains are divided into network, following the loading limits of the road, and on-road. Depending on the circulation, ordinary trains are distinguished, which are disbanded after unloading, and ring trains with a constant composition, which, after unloading, return empty to the same station for reloading.

Ring routes are organized in areas with stable economic ties. With ring routing, the reliability of providing loading with rolling stock is increased, the costs of preparing empty cars arriving for loading are reduced, as a result of which the route speed is increased. The most economical are ring routes of specialized wagons, especially in directions where their organization does not increase the total empty mileage of wagons. At the same time, the safety of goods and rolling stock is ensured as much as possible, loading and unloading operations are accelerated. Ring routes are used primarily for the transportation of bulk cargo - coal, ore, building materials, oil cargo, cars, grain. To increase the efficiency of ring routes in directions with stable cargo flows, they are also loaded in the direction of an empty run after unloading. Using the solid threads of the schedule of such trains in the loaded and empty directions, carrying out loading scheduling, it is possible to increase the stability of transportation.

A necessary condition for the organization of routes is the presence of a total daily volume of loading by all consignors of at least one train; the daily unloading capacity of all consignees of the destination station of the route must also be at least the number of cars in the arriving train. A sufficient condition for including individual correspondence (jets) of car flows into the sender's routing plan is the requirement that the total additional costs for completing the sender's route at the loading station and organizing its unloading at the destination station in comparison with non-route departure and arrival should not be higher than the savings obtained in paths. The savings along the route consist of savings from passing technical stations without processing, savings from faster progress through the loading and unloading sections of routes compared to combined trains, if the loading and unloading stations are intermediate.

In general, the plan for the formation of trains should provide the least total demurrage of cars both during their accumulation and during processing, as well as minimum operating costs.

To evaluate the plan for the formation of trains, its indicators are calculated. The main ones include the total labor costs (in car hours), including the accumulation of cars and their processing; level of sending and step routing; average mileage of wagons without processing; operating costs depending on the formation plan.

2.6 Block layout functional diagram

The BMRC equipment is subdivided into a type-setting (route set), an executive group (layouts for installing and opening routes) and schemes for controlling and controlling outdoor objects.

Dial group blocks. Schemes of the type-setting group of the BMRTS are designed to implement the route method for controlling arrows and traffic lights.

Produced arrangement of blocks at the station. The following blocks were placed:

NMI - circuit assembly of a single shunting traffic light (Spanish MI);

NMIIP - a circuit assembly of a shunting traffic light from a dead end or for two traffic lights standing in the alignment or from a section of the track (Spanish MII and MIII);

NPM-69 - a circuit assembly of a train traffic light with a shunting indication (app. VI, VII, VIII, VD);

НСОх2 - circuit assembly of a single arrow (Spanish C);

NSS - a circuit assembly of a paired arrow (Spanish C).

Fixing the beginning, type and direction of the route.

The same button on the control panel can be the initial and final, and if there are alternative routes, the buttons of shunting traffic lights can be used as alternative ones. Therefore, the BMRC system provides for the installation of a block of directions NN, which for each route determines its beginning, type (train or shunting) and direction of movement (odd or even). To do this, the contacts of the push-button relays that control the LV block are divided into four groups depending on the type and direction of routes: odd train (HV wire), even train (HF), odd shunting (VNM) and even shunting (HFM). By pressing the first button in each of the groups, the corresponding relay of the direction P, O, PM and OM is turned on. The P and O relays are switched on directly by the contacts of the push-button relays, the PM and OM relays - through the auxiliary relays VPM and PTO.

After operation, the train relays of directions P or O are blocked through the contacts of the push-button relays of the other three groups, and the shunting PM or OM - through the contacts of the push-button relays of another shunting group, because. When shunting routes are set, train push-button relays do not work. This ensures that the armature of the switched on direction relay is securely held when any button is pressed until the circuit for setting this route is completed and the buttons are released (wires BO1 and BO2).

The contacts of the switched-on direction relay supply positive power to P through the contact of the OH set cancellation relay to the direction buses H, H, NM or FM, and this pole is removed from the TN, TC, TNM or FM buses. Switching on of the direction relay is indicated by an indication on the scoreboard in the form of arrows with a green (when setting train routes) or white (when shunting routes) stripe.

Relays VU, VU1, NVV and FVV are used in the auxiliary control mode in case of a malfunction of the route dialing circuits. In this mode, when the second (end) button is pressed, the CPV relay is turned on, supplying the power supply pole M of the auxiliary control IN, ICH, OSI or HMI. The CPV relay is used to turn off the PKU power pole when setting alternative routes, when the second (optional) button is pressed. This prevents the main route from being set instead of the variant route. Route dialing scheme. Such circuits are built by connecting the block of the dial group with four electrical circuits, topologically displaying the plan of the station:

1 - push-button relays NKN and KN;

2 - automatic push-button relays AKN;

3 - control pointer relays PU, MU;

4 is a diagram of the correspondence of the SS. To switch these circuits, control pointer relays PU, MU, anti-repetition relays OP, PP and MP, auxiliary intermediate relays VP, auxiliary push-button relays VK and VKM are used.

Button relays. Relays NKN and KN are installed in the set-up blocks that control traffic lights, and turn on when the corresponding buttons on the control panel are pressed.

The NPM block contains two push-button relays: NKN, which is activated when the train buttons are pressed, and KN, which is activated when the shunting buttons are pressed.

The button relays of the NMI block are switched on through an additional button relay K of the NMID block.

After releasing the corresponding buttons, the self-locking circuits of the KN and NKN relays are turned on and are turned off when the rear contacts of the relay PU, MU, located in neighboring blocks NSS or NCOx2, are opened along the first chain of interconnections

Anti-repeat relays. The relays OP, PP of the NPM block and the relay MP of the NMI, NMIIP and NMIIIAP blocks are designed for a single switching on of the control-sectional CS and signal C relays of the executive group. Anti-repeat relays are activated in those blocks in which the train or shunting button was pressed as the initial one.

Until the opening of the corresponding traffic light, the anti-repeat relays are powered by a self-locking circuit through the rear contacts of the signal relays and turn off when they are triggered.

Auxiliary pushbutton relays. The VK and VKM relays of the NPM block and the VKM relays of the NMI, NMIIP and NMIIIAP blocks provide power supply to the circuits of the relays AKN, PU and MU, SS of route dialing circuits. The VKM relays include the final shunting relays KM in the corresponding blocks of the executive group. Auxiliary limit relays are switched on in those blocks in which the train or shunting button was pressed as a final one.

Before the route is closed, the auxiliary final relays VK and VKM receive power through the self-locking circuit through the front contacts of the closing relays of the last section of the route and lose power when they are turned off.

Control switch relays. The PU and MU relays are installed in the NSOx2 and NSS typesetting blocks and serve to transfer running and guard arrows along the route.

Control switch relays are included in the third chain of interconnections in series within one element of the route located between two adjacent buttons.

The control switch relays PU and MU are switched on after setting the route as a result of opening the front contacts of the closing relays З, which turn off the self-locking circuit of the relays VK, VKM and VP.

Angular pushbutton relays. The UK relays are installed in the NSS blocks and are designed to select the route of the main route. These relays are switched on by the contacts of the push-button relays of those buttons, which, firstly, are located according to the plan of the station relative to the given exit from the side of the haul, and, secondly, this exit makes it possible to set the route according to its minus position. Topologically, the UK relay contacts in sharp corners circuits of the AKN relay, which correspond to the corners of the station plan, formed by the exit and the straight path when moving from the side of the stage. This allows you to set a route for both positions of the exit arrows. To exclude bypass circuits, the UK relay receives power through the diodes of the BDSH block.

Automatic pushbutton relays. AKN relays are installed in NMI and NMIIAP stacking blocks. They are intended for automatic translation of arrows in routes containing two or more elements, i.e. in routes that, in addition to the start and end, have intermediate buttons.

The AKN relay, when activated, closes the switching circuit of the NKN and KN push-button relays in the intermediate dial blocks.

Auxiliary intermediate relays. The VP relays are installed in the NMI, NMIIP and NMIIIAP stacking blocks. They are designed to supply the power pole to the control switch relay circuit PU and MU at the boundaries of the elements.

The VP relays in these blocks are activated if a train route is set past this shunting traffic light, or a shunting traffic route in the opposite direction.

Matching scheme. The fourth circuit of interconnections is a CC correspondence circuit, which is designed to turn on the train and shunting initial relays H with checking the compliance of the actual position of the arrows and the command to switch them. This verification is achieved by sequential inclusion in the correspondence circuit of the contacts of the control switch relays PU, MU and the control relays PC, MK of all running and guard switches included in the specified route.

The route dial circuit returns to its original state after the signal relay C is turned on.

Cancel set. At erroneous actions on the control panel, DSCP can reset the dial-up group circuits by pressing the OH button. The OH relay, turning off, disconnects the power poles. This turns off all route dial relays.

The OH relay, together with the OUT relay, prevents the accumulation of route assignments through a section that is occupied or closed in other routes. This excludes a dangerous failure - the transfer of arrows under a moving train in case of loss of a shunt on the track circuit.

Auxiliary management. In the event of a failure of the route set (more often, the correspondence scheme), the DSCP has the ability to establish a route using the auxiliary control mode. To do this, the running and security arrows along the route are translated separately, and then the VU button is pressed and, without releasing it, the start and end buttons of the route.

2.7 Arrow control scheme

For the neck of this station, a five-wire control circuit for electric switch drives was selected. It is used when using turnout electric drives with three-phase AC motors for central power supply of floor devices. This circuit has a number of advantages over a similar two-wire control circuit:

Duplication of cable cores is not required;

Electric motor without commutator with three-phase motor have smoother running and longer service life;

The scheme is reliably protected from false control when confusing the connection points of line wires;

Lower cost of EC construction;

Reliable work when transferring arrows;

The circuit includes relays: NPS - neutral starting pointer relay type NMPSH 1200/220; PPS - polarized starting relay type PMPUSh; OK - general control type KMSh-3000; BFK - block of phase control type FK-75.

To move the arrow to the minus position, the chipboard turns the handle of the switch switch. The starting relay LPS is activated with control of the absence of the closure of the switches in the established route (the front contact of the relay Z) and the freedom of the switch section from the PS (the front contact of the SP relay), which, by closing the front contact, supplies power to the winding of the PPS relay. It operates on reverse polarity current and supplies power to the motor winding. Arrow translation starts. In the five-wire circuit, a valve control circuit is used, but the control of the positive and negative positions is carried out on different pairs of linear wires, which ensures the reliability of the control circuit.

2.8 EC cable networks

Cable lines and networks are a complex of structures and devices designed to ensure the transmission of signals and electrical energy. Cable networks of automation and telemechanics at the stations are designed to ensure the functioning of the system of EC devices.

The cable brand SPBG is selected.

Cables connect the floor devices of the EC (switch electric drives, traffic lights and track circuit devices) with the guards and the guards among themselves. Cable networks are made up on the basis of circuit diagrams for switching on outdoor devices using a schematic plan of the station with signaling. In a cable network, objects of the same type are grouped with the help of branching couplings RM, installed in the areas of the greatest concentration of objects at the object closest to the post. A group cable is laid from the EC post to the RM coupling, and individual cables are laid from the RM coupling to each object. The place for the RM coupling is chosen in such a way as to exclude a return towards the EC post coming out of the individual cable coupling. When developing cable networks, it is necessary to strive to reduce the number of cables laid. In cable networks of switch electric drives and traffic lights, serial piping of three and, as an exception, four objects is allowed.

Branching joints are initially designed on the main cable route on a two-strand plan of the station, and then they are placed on the cable network diagram and group and individual cables of EC outdoor devices are connected to them. Each clutch has its own name (S - signal, St - switch, P - supply, R - relay) and ordinate. Cable network of traffic lights

The cable network of traffic lights includes circuits of output, route and shunting traffic lights; relay cabinets for input traffic lights and crossing signaling cabinets; light route indicators and light position indicators; light indicators with a vertically luminous arrow. The relay cabinet of the input traffic light includes control and monitoring circuits for input traffic lights, powering the cabinet, linking electrical interlocking devices with interval control systems for train traffic, powering the rail circuits of the approach section and the first station, boundary with the span of the rail circuits, the disconnector of the high-voltage signal line of the interval control system train movements. The range for controlling the lights of output, route and shunting traffic lights with lamps of 15 W, 12 V with step-down transformers ST-4 when powered from a centralization post without duplication of cores is 3 km. Reducing the cable section to 0.636 mm2 does not affect the traffic light control range. The number of wires to the traffic light M is found according to the schemes of typical solutions. Output traffic lights have three central power modes: daytime (voltage 220 V), night (voltage 180 V) and low voltage mode (voltage 127 V). The number of cable cores to the relay cabinet of the input traffic light is determined by the schemes for switching on the input traffic lights and linking the electrical interlocking devices with the systems of interval control of train traffic. The control range of the input traffic lights is practically unlimited, since the lamps receive central power and AC backup from the battery of the centralization post through semiconductor converters . In sections with AC electric traction, linear circuits of systems for interval control of train traffic, as a rule, run in the main communication cable. Light route indicators and light position indicators are usually powered from a 220 V electrical interlocking station (lamp power 25 W). The number of wires to the pointers is determined by the set of lamps for the corresponding indication. The number of cores in the wires is calculated analytically or according to the nomogram. For a light route indicator without duplication of direct and return wires, the maximum switching range is 550 m. If there are two cores in the return wire, and one each in the direct wires, then the maximum range will increase to 730 m. The nomogram displays the relationship between the voltage drop (AU ), cable length L and the number of indicator lamps included in one core. To use the nomogram, it is necessary to know the numbers of the burning lamps of the light route indicator used for all its readings. Suppose the pointer has two digital readings - 1 and 4. If the voltage drop in the return wire exceeds 20 V, then it is necessary to increase the number of wires in the direct wire with the maximum number of lamps in order to reduce the number of lamps per wire. For the Green Stripe light indicator, with a cable length of up to 3 km, duplication of ZLO, 03P0 wires is not required, with a length of up to 4 km, duplication (3 cores) is required, over 4 km - 4 cores. For light indicators with a vertical luminous one or two arrows (lamps with a power of 15 W, 12 V), the allowable distance without duplicating the wires of the indicator with one arrow is 8 km, the indicator, south0 of the indicator with two arrows is 4 km. The diagram of the cable network of traffic lights is shown for half of the large station. The station is equipped with electrical interlocking devices, and the tracks to it are equipped with a system for interval control of train traffic - a double-track automatic blocking of alternating current 50 Hz. The relay cabinet of the input traffic light includes cables for communication with the equipment of the electrical interlocking post; cables connecting traffic lights H and ND; communication cable with a high-voltage signal line of automatic blocking and a power cable with a cable box KYa-6; cables connecting the input traffic light or the EC post with the equipment of the track circuits of the 1PP approach, 2UP removal, non-pointer NP and turnout 3-9SP sections. Each such cable has a length, the number of working and spare cores, the name of each core according to the wiring diagram. To turn on the output and shunting traffic lights, five branching couplings are used: C1, C3, C5, C7 and C9; each of them has an installation ordinate. Places of installation of couplings are chosen in the area of concentration of a group of traffic lights. It is recommended to include no more than two traffic lights in one cable so that the maximum length of one piece of cable does not exceed 200 m; laying the cable towards the centralization post should be avoided. Each cable has a length, capacity, number of spare cores. Under each main cable in the diagram, a rule is given for counting the number of working cores. With a greater distance, the cable cores are duplicated; cable core is determined by the calculation of the voltage drop across the relay. In the diagram, relay choke-transformers are designated as terminal ones, since they do not have clamps for use as feedthroughs. Relay transformers can be included as intermediate; for direct current electric traction, if one relay transformer is installed in the waybox TYa-I (drawing no. 7324, assembly I), in this box it is possible to cut the cable for another six relay transformers. If two relay transformers are installed in the waybox TYa-I (assembly II), then you can cut the cable for three more relay transformers. When compiling cable networks of supply transformers, it should be taken into account that the supply transformers of track circuits are grouped into separate supply beams so that a power failure in one beam disables, if possible, a smaller number of routes. The supply transformers of the main and encoded paths are grouped into separate supply paths. According to calculations, the current of one beam of track circuits of alternating current with a frequency of 25 Hz can be no more than 0.68 A. Then two beams with a total load of not more than 1.36 A can be connected to one frequency converter PCh50 / 25-300. Maximum cable length without duplication lived in the wires between the supply transformer and the centralization post with DC electric traction is 1500 m, with AC electric traction and autonomous traction - 3000 m. The station has two-strand track circuits of alternating current with a frequency of 25 Hz, the main tracks are coded. In the cable network of relay transformers, four branching couplings are used, to which the choke-transformers are connected as final ones with two cable cores. For track sections 2UP and NP, the devices of the relay ends are placed in the relay cabinet RSH of the traffic light Ya; maximum removal a travel relay from the relay transformer of the section NP 1555 m. For the ends of track circuits 13-19B and 29V, travel boxes are shown - transformer boxes TYa-I with relay end equipment; track box 29B intermediate. When drawing up the scheme, the possibility of joint laying of the relay wires of the uninterrupted power supply rail circuits with the relay wires of the code rail circuits of the main tracks was taken into account. In the cable network of supply transformers, all supply choke-transformers are included as end transformers in four branching couplings - without duplication of cable cores, since the length to the most remote supply transformer 3-9 is 1480 m. Supply transformers are grouped into two beams: in a beam / included choke-transformers along the route of departure, and into beam 2 - along the route of reception. With direct current electric traction, the calculated currents consumed by the primary windings of the supply transformers, depending on the length of the two-strand track circuits, are for non-coded track circuits with one relay 0.025-0.045 A, with two relays 0.027-0.068 A; for coded track circuits, respectively, 0.029 - 0.061 A and 0.036 - 0.087 A. For branched track circuits, it is necessary to take into account the length of the branches to the side tracks. The current consumed by the beam devices is 0.35--1 A. In the presence of single-strand track circuits, the consumed currents are 0.05--0.09 A for unbranched track circuits, and 0.09--0.12 A for branched ones. Calculation of the number of cores for supply transformers, it is carried out on a variable cable section, depending on the distribution of loads in the supply transformer circuit. Cable network of turnout electric drives

When drawing up a cable network diagram, the capacity of the cables of the cable accessories and the maximum distance of the electric drives from the branching joints, which should not exceed 200 m, are taken into account. The cable network diagram is given for one half of a large station. The calculations are given for the SP-6 pointer electric drive with a DC motor MSP-0.15-160 V with a central power supply of 220 V, controlled by a two-wire circuit (cable core diameter 1 mm, cross-sectional area 0.785 mm2). The calculation of the cable network consists in determining the number of cores of the control and control circuits of the switches, taking into account the dual control of the switches 23 and 29 of the automatic cleaning circuits of the switches from snow and the electric heating circuits of the switch electric drives (the numbers are put down under the cable, and above it - the total number of wires, taking into account the spare ones) . On the primary winding 179.1 (220 - 40.9) V. Then in the nearest column (180 V) the cable lengths to the electric drives should be within 70 - 265 m, which corresponds to the actual lengths of the cable laid on the diagram. Therefore, two wires must be laid from the secondary winding of POBS-5A to each drive of arrows 1, 3 and 5/7. In track box B there are two POBS-5A - one for the 9/11 switches and the other for 13/15 and 17/19. A voltage of 220 V is supplied to each of the transformers from the post through two cable cores. Voltage drop to the first POBS-5A 12.9 V; the voltage on the primary winding is 207.1 V. In the nearest column (210 V) of the table. 9.8 the length of the cable to the electric drives must be within 45-195 m for the first switch, 140-60 m between the switches, which also corresponds to the actual lengths. The voltage drop to the second POBS-5A is 29.8 V, and the voltage on the primary winding is 190.2 V. According to the column (190 V), the cable lengths for the first paired arrows should be within 5 - 145 m, and between the arrows - 140 -60 m. The voltage drop at POBS-5A in the track box is 15.9 V, and the voltage on the primary winding is 204.1 V. In the column (200 V) of the table. 9.8 the length of the cable to a single switch 21 should be within 105--315 m, for the first paired switch 27 - 25-- 170 m, and between the arrows - 140--60 m. Voltage drop at POBS-5A box G 11 .9 V, the voltage on the primary winding is 208.1 V, the cable length is taken according to the column (210 V) of the table. 9.8. As a result, three digits are put under each individual and group cable, for example, for a group cable between splitter couplings ST1 and STZ - 12 + 4 + 2. For the shunting column MK.1 with arrow handles 23 and 29 according to the plan of the station located from the centralization post at a distance of up to 1100 m near the controlled switches (where the originator should be), determine the number of cores in the cables laid from the ST7 splitter in three directions: to the switch electric drives 23 and 29, to the shunting column MK1 and to the centralization post. In a two-wire circuit for controlling electric switch drives, when duplicating two cores of the direct wire and with one core in the return wire (the length of the cable from the centralization station to the switches does not exceed 910 m), the number of wires in the cable from the ST7 splitter to switches 23 and 29 is 8 (including including two cores for each switch switch), from the splitter to the shunting column MK1 - 17 cores (including one wire for each switch switch and switch section, two wires for each arrow indication), from the centralization post to the splitter couplings - 15 cores (including one core for each turnout switch and turnout section and three cores for the linear wires of the circuit). The total number of a group cable is 24 cores of paired twisting, including 15 cores for control, 3 for blowing, 2 for heating and 4 spare.

3 . TECHNOLOGICAL PART

3. 1 Checking the tightness of pressing the point against the frame rail

The size of the gap between the blade and the frame rail is the most important condition for ensuring the safe rolling of the wheelset from the frame rail to the blade and back.

The need to normalize this gap arose with the advent of the first systems of mechanical centralization in order to control the ingress of a foreign object between the wit and the frame rail. In addition, with the introduction of these systems, the additional effort to squeeze the wit, created by the counterweight of the manual transfer mechanism, disappeared.

With the advent of electric interlocking and electric drives with a fixed stroke of the gate, the wit, transferred to a certain distance, began to close mechanically and remain in its place, regardless of the size of the gap between it and the frame rail. In other words, the gap could have arisen not only due to the ingress of a foreign object, but also, more likely, as a result of the widening of the track, wear of the parts of the swivel joints of the turnout sets, etc.

The situation escalated with the advent of heavy type turnouts. When using them, the transfer forces acting on the gate and switch set have significantly increased. When the electric drive is working on friction, they increase even more. For this reason, there are significant elastic deformations of the working rods and displacement of the articulated joints. As a result, the pointer can close when the thickness of the probe is 2-2.5 times greater than the gap between the point and the frame rail, including more than 4 mm.

...Similar Documents

Station throat routing. Selecting the type of track circuits. Single-strand and double-strand plans of the station neck. Calculation of ordinates of arrows. Signaling station traffic lights. Ensuring traffic safety by electrical interlocking devices.

term paper, added 08/04/2015

Characteristics of the neck of the station and the rationale for choosing a centralization system. Routing of a single-line and two-line plan of the station neck with the calculation of the ordinates of the arrows and signals. Selecting the type of track circuits. Signaling station traffic lights.

term paper, added 04/01/2013

Single and double line station plan. Cable networks of traffic lights, switches, rail circuits. Block diagrams and characteristics of power panels. Production of works on centralized arrows. Calculation of the throughput of the station, change in speed.

thesis, added 03/10/2013

The order of placement of traffic lights and the calculation of the ordinates of arrows and signals. Sewerage of reverse traction current. Coding of track circuits at the station. Construction of cable networks to connect the post of electrical interlocking with objects of management and control.

term paper, added 03/14/2014

The value of automation devices in railway transport. Characteristics of the station and justification for the choice of centralization. Arrangement of traffic lights with their complete signaling and determination of the ordinates of arrows and signals. Type of blocks, their device and purpose.

term paper, added 10/27/2015

Development of computer and microprocessor systems. Schematic plan of the station. Two-line plan of the station. Microprocessor centralization of arrows and signals MPTs-I. Scheme of controlling the lights of output traffic lights. Interface with arrow control cabinet.

thesis, added 03/31/2015

Construction of the train speed curve. Arrangement of auto-blocking traffic lights on the stage along the speed curve. Arrangement of station traffic lights and insulating joints. Determining the ordinates of arrows and traffic lights. Making a list of routes.

term paper, added 01/24/2016

Characteristics of the designed centralization system. Post equipment, placement and installation system of devices. Routing set of block route-relay interlocking: basic functions and modes of operation. Control-sectional and alarm relays.

abstract, added 07/30/2015

Classification of electrical centralization systems and their structural scheme. Isolation and operating modes of track circuits. Types of traffic lights and their colors. Types of turnout electric drives. Maintenance of centralized switches, elimination of damage.

thesis, added 03/29/2012

Single-line plan of the station, its structure and elements. Development and maintenance of the dependency table. Nine-wire switch drive control circuit. Dependencies implemented in the signal chain. Arrangement of traffic lights on the stage along the speed curve.

Department: "Automation and telemechanics in railway transport"

On the topic: "Equipment of the station with BMRTS devices"

Completed by: Abdullaev R. B.

Student group AB - 174

Checked by: Tsoy N. G.

Tashkent

2012

Assignment for the course project…………………………………………………….3

Introduction………………………………………………………………………………4

1. Operational and technical part

Characteristics of the designed centralization system. . . . . .5

Post equipment, placement and installation system of devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Functional diagram of the placement of blocks "according to the plan" of the station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Maintenance of EC post devices

And safety precautions in the production of works. . . . . . . . . . . . .9

2. Route set BMRC

2.1. Functions and operating modes of route dialing. . . . . . . . . . . . eleven

2.2. Determining the direction of movement and category

Route. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.3. Construction and operation of the angular relay circuit. . . . . . . . . . . . . . . . . 15

3. Executive group BMRC

3.1. Overlaying route dialing schemes on an executive group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2. Control-sectional and alarm relays. . . . . . . . . . . . . . . . 17

3.3. Closing and automatic opening of routes. . . . . . . .19

3.4. Cancellation and artificial cutting of routes. . . . . . . . . . . . . 22

Bibliography. . . . . . . . . . . . . . . . . . . . . . . . . . . ……………….... . . .24

Application

1. Schematic plan of the station. . . . . . . . . . . . . . . . . . . . . . . . . Sheet 1

2. Block plan of the station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Sheet 2

3. Switching on the relay block of directions and group circuits. . . Sheet 3

4. Scheme of angular relays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Sheet 4

5. Setting, closing, monitoring and opening the route. . Sheet 5

6. Timing kits. . . . . . . . . . . . . . . . . . . . . . . . Sheet 6

INTRODUCTION

Among the devices of railway automation and telemechanics with And Plant management systems play a critical role. The processing speed of trains at stations is decisively determined e lays throughput railways. The safety of train traffic in general largely depends on the safety of movement at the station. These movements have features the movement of trains on turnouts, the simultaneity of movements and the presence of two different types movements (train and shunting).

Ensuring high throughput and carrying capacity, without h dangers of train traffic on railway lines, an increase in the processing capacity of stations, as well as an increase in production O efficiency and improvement of working conditions of railway workers using at yut means of automation and telemechanics.

The introduction of automatic blocking on double-track lines increases their throughput by 2-3 times compared to semi-automatic blocking. Auto-blocking together with the control room centralization A tion increases the capacity of single-track lines by 40-50%. At the same time, 60-70 people are released for every 100 km of lines. With operating state. Implementation of electric control panel devices And zation allows to increase the throughput of stations by 1.5-2 times, reduce the staff of turnouts on duty and other people on duty in the environment. d there are 35 people for every 100 centralized arrows.

The main type of electrical interlocking currently used is the relay interlocking of switches and signals, in which relay equipment with high reliability is used for control, which ensures the requirements for the safety of train traffic.

Relay interlocking, in accordance with the requirements of the PTE, does not allow the opening of the input traffic light when the route is set to a busy track; translation of the arrow under the composition; opening signals, respectively at route, if the arrows are not set in the proper position, and the signals of hostile routes are not closed; transfer of an arrow included in the route or opening a signal of a hostile mar w rue with an open signal fencing the established route.

At the stations, depending on the number of switches, signals and the size of the movement, several types of relay circuit systems are used. n trawling, one of which is block route-relay centralization (BMRTS), which has found wide application at precinct, marshalling and intermediate stations with more than 30 switches and a significant amount of work.

The purpose of this course project is to develop technical solutions for equipping the station with BMRTS devices.

1. Operationaltechnical part

1.1. Characteristics of the designed centralization system

The block route-relay system of centralization (BMRC), due to its industrial principles, has become widespread at medium and large stations, as well as industrial railway transport. The BMRC system uses route control of arrows and traffic lights by pressing buttons according to the “from where to where” principle. Two groups of relays are used: dial-up group and executive relay group. The type group serves to transmit orders for the transfer of all arrows participating in the route. It also ensures the safety of train traffic, but does not fulfill the requirements of the PTE and therefore is based on a relay of the second class of reliability of the KDR type. The relay executive group performs route closure, traffic light opening, route opening by train, route cancellation and artificial route opening, ensures train traffic safety, fulfills the requirements of PTE for EC devices and therefore is built on the first reliability class relay of NM and KM type.

The type-setting and executive groups of the relay are used in block mounting, which can significantly reduce the amount of installation work during construction, and speed up the commissioning of centralization devices, and further improve their service conditions. Stacking blocks of the same size, in which up to six relays of the KDR type are installed, except for the BDSH block, which is located in the NMSh relay housing, where 20 diodes are installed, for circuit decoupling of the UK angular relay. Executive blocks are of small type (block C), where three relays of the NM type are installed and large types (blocks PS, SP, UP, etc.), where it is possible to place up to 9 relays of the NM type, but, as a rule, one of places are occupied by resistors.

The projected BMRC uses a two-wire switch control circuit with a PS-220M unit, central power supply and central dependencies are used, i.e. all dependencies between arrows, traffic lights and track circuits are performed at the EC post, an input traffic light control scheme with double-filament lamps is used. The control apparatus is presented in the form of a control panel with a trough-type display with route control of arrows and signals. One stage of closing and sectional opening of the route is applied. A batteryless power supply system is used, i.e. there is no 220V working battery, but a 24V starter battery (for starting the DGA), a 24V control battery and a 60V communication battery are used. The station is equipped with track circuits of alternating current with a frequency of 25 Hz, with a traveling relay DSSh-13, as well as electric switch drives of the SP-6M type.

1.2. Station equipment, placement and mounting system

Devices

Approximately 70% of all BMRC equipment is located in functional blocks, which are manufactured at factories in the form of standard designs with completed installation. BMRC schemes for stations with any number of arrows and traffic lights are assembled by interconnecting typesetting and executive blocks in accordance with the topology of a single-line station plan. The block construction of electrical interlocking makes it possible to simplify the design of devices, reduce the time of installation work, and improve maintainability during the operation of existing installations.

BMRC equipment and power supply devices are located in the building of the EC post. The main premises of the EC post are: hardware, relay, communication, etc.

The design of the BMRC is reduced to a set and connection of typical circuit blocks located along the track development of a given station. Relay blocks have a plug-in connection in the current circuit, which allows, in case of a malfunction in the block, to replace the block without disturbing the work of centralization.

The BMRC equipment is subdivided into typesetting (routing set), executive (route installation and opening circuits) groups and control and monitoring circuits for outdoor objects. Schemes of the type-setting group of the BMRTS are designed to implement the route method for controlling arrows and traffic lights. The relays located in the blocks of the dial group record the actions of the station attendant on the control panel and automate the transfer of arrows along the route and the opening of traffic lights.

Typical relay blocks are placed on free-mounted racks, the electrical installation of which is carried out in the factory according to individual projects for a particular station, while the blocks of the dial-up and executive group are installed together on the same racks in order to reduce the cost of the installation wire and intra-gang cable.

The number and order of placement of blocks on racks is determined by the general functional diagram that reproduces the station's track plan with centralization objects. Along with the relay blocks in the upper part of the cabinets there is a row of NMSh, KMSh type relays and two rows of terminals for connecting mounting wires.

BMRC uses 8 type-setting blocks and 12 types of executive group blocks. In place of one block of the executive group, two typesetting blocks can be installed.

1.3. Functional diagram of the placement of blocks "according to the plan" of the station

Blocks at BMRC are arranged according to the schematic plan of the station, which indicates: numbering and specialization of receiving and departing tracks; numbering of switches, switch-track and non-switch sections; all main iso-junctions, repeaters of input main and additional traffic lights, as well as output combined with shunting and repeaters of shunting traffic lights are placed; signal buttons for train and shunting signals are placed, located on 1 sheet of the course project.

Arrangement of blocks of a typesetting group:

NPM - to control input, output and route traffic lights; can be used for a shunting traffic light from the track section behind the entrance traffic light, as well as for the final train button;

HM I - a control unit for a single shunting traffic light located on the border of two switch isolated sections; also applies to the option button;

NM I D - additional block for six HM blocks I ; contains six push-button relays - repeaters of the buttons of the control panel;

NM II P - a control unit for a shunting traffic light that allows movement from a non-centralized zone, as well as for one of the two shunting traffic lights from a section of the track or for one of the two traffic lights in the alignment;

NM II AP - the same for the second traffic light from the track section or traffic lights in the alignment; used in conjunction with the HM block II P;

НСОх2 - control unit for two single arrows;

NSS - control unit for twin arrows;

HH - direction block, fixing the type and direction of the given routes;

NPS - a block that controls the sequential transfer of arrows during the main power supply; contains three sets of control equipment;

BDSH-20 - a block for turning on angular push-button relays in NSS blocks, contains diode decoupling circuits.

Schemes of the BMRC executive group are designed for installation, closing, opening and artificial cutting of routes with checking the conditions for the safety of train traffic. Arrangement of blocks of the executive group:

In I - a block of the output traffic light, combined with a shunting one, with a three-digit signaling;

In II - the block of an output traffic light on two directions at the three-digit signaling; it is also used for the exit traffic light from the main track in the presence of alternative routes;

BIII - a block of the output traffic light combined with a shunting one, with a four-digit signaling;

VD - additional to blocks B I-BIII ; it is also used to control the input traffic light with local power supply of lamps;

P - block for monitoring the status and absence of hostile routes on the receiving-departure route;

joint venture - block for monitoring the state, closing and opening of the switch section;

UP - a block for monitoring the state, closing and opening of the non-arrow section (section of the track in the neck of the station);

WITH - pointer position control unit;

PS - starting pointer block; designed to control and control two (single or paired) arrows;

M I - a block of a single shunting traffic light located on the border of two switch isolated sections;

M II - a block of a shunting traffic light located in the alignment (on the same ordinate) with a traffic light of the opposite direction; also applies to traffic lights from a non-centralized area;

Mill - a block of a shunting traffic light from the section of the track in the neck of the station, as well as a shunting traffic light from a specialized receiving and departing track.

Units installed on free cabinets not according to the station plan:

HM I D; HH and one reserve HHr;

BDSH-20; PS starting switch block, large size, PS-220M is installed one for two single switches or one for two ramps or one for a ramp and one switch; BMVSH blocks (small-sized time delay block with plug-in fastening) are made in the NMSh relay case, 4 blocks are installed per station:

1. OSB cancel zener block with 6s time delay.

2. MSB shunting zener diode unit with a time delay of 60 s.

3. PSB train zener diode unit with a time delay of 180 s. It is used when a train route is canceled when the approach section is busy.

4. ISB artificial opening zener diode block with a time delay of 180 s.

1.4. Maintenance of post devices of the EC and safety precautions in the production of work

The main types of maintenance work are: checking the dependencies in accordance with the requirements established by the PTE, checking the operation, inspection, measuring parameters, characteristics and bringing them to normal, adjusting, cleaning, lubricating, painting, replacing worn parts and assemblies, replacing with the established frequency devices for repaired and tested in the RTU, restoration of the correct operation of devices in the event of failures, work to improve reliability, currentrepair. Maintenance is carried out, as a rule, without switching off devices from dependence.

Preventivework is performed after a certain time after the end of the previous maintenance. Repair work is carried out with the shutdown and disassembly of devices within a certain time frame.Recoveryworks provide immediate elimination of failures.

Organization Maintenance possible at a distance of signaling and communication and is regulated by the PTE and the Instruction for the maintenance of signaling devices. Troubleshooting and maintenance are provided by employees of the distances in compliance with the requirements of the Instructions for the movement of trains and shunting work on railways Russian Federation, Instructions for ensuring the safety of train traffic during the performance of maintenance and repair of signaling devices (TsSh / 4397), as well as developed technological processes and technical instructions.

To establish a unified maintenance work schedule, there are technological maps. All main works are divided into three groups: work related to turning off devices, work performed with the consent of the chipboard and with a preliminary entry in the inspection log without turning off the devices, and work performed with the consent of the chipboard without an entry in the inspection log. The first group includes such works as replacement of the electric drive or individual units, switch headset units, cable to the electric drive or installation in the electric drive and other similar types of work. The second group of works includes scheduled checks and inspection of devices. The third group includes work "on replacing lamps in traffic lights of a signal transformer and adjusting the voltage on the lamps, replacing plug-in devices (relays), display lamps, etc. A complete list of works for each group is given in the Instructions for Ensuring Traffic Safety during the Production of maintenance work on devices STsB (TsSh/4397).

The inspection log indicates the results of the inspection, the detected malfunctions and damages, the start and end time of work, the performer or responsible work manager. Within one EC post, while maintaining the use of signals, it is allowed to simultaneously turn off for repair no more than one switch and no more than two track circuits.

Periodic inspection of the monitoring equipment and its repair is carried out in the repair and technological areas (RTU or instrumentation) according to technological maps, which indicate the type of product or assembly, the items performed from the list of operations, measuring instruments, tool and materials, performer. At distances, okolotkovy and brigade methods of maintenance have found application. In the circumferential method, all devices are serviced by an electrician and one or two electricians. The okolotok covers one small station with an adjacent span; Large stations are divided into several districts. Six to eight neighborhoods make up the site; the work of the electrician and electricians of the site is organized and controlled by the senior electrician. With the brigade method, one integrated or two or three specialized maintenance teams are created on the site. A team of six to ten people is headed by an electrician-foreman or a senior electrician. The work in this case covers the annual and four-week device maintenance schedule.

When working on railway tracks, in order to ensure the safety of train traffic and the work of workers, the place of work is preliminarily fenced off with stop signals, speed reduction, and the sign “Sound signal by locomotives”.

When working on centralized arrows, wooden liners are installed between the retracted wit and the frame rail against the electric drive rods. In conditions of poor visibility, work on the railway tracks is carried out by a group consisting of at least 2 people, one of them is only responsible for monitoring the movement of trains. When carrying out work at a traffic light, you cannot work in 2 persons at different levels. The working tool must be in good condition with good insulation on the handles and other places to be insulated.

2. Route set BMRC

2.1. Route dialing functions and operating modes

All relays of the dial-up group are placed in closed blocks, which are mounted and checked at the factory according to standard schemes. The type group allows you to apply the route control of the arrows instead of the separate one. If, with separate control, the switches are set along the route by moving the turnout switches, or by pressing the buttons of all the switches included in the route, then with route control, the switches included in the route are switched by pressing two or more buttons in succession, which significantly reduces the time for preparing routes and increases speed centralization.

The main relays of the dial group, which carry out all of the above actions, are: KN (NKN) push-button, fixing the pressing of route buttons; DCA automatic push-button, which determines the main variant of the route and allows you to dial complex routes by pressing only two buttons the beginning and end of the route; as well as dial shunting routes at the traffic lights by pressing only two buttons; P admission; About departure; PM shunting on reception; OM shunting by departure (direction relay to determine the category and direction of the route).

The directional relays are switched on according to a special scheme with mutual interlocking, which allows to simultaneously excite one relay of the category, the button of which was pressed first. The excitation of the direction relay allows you to dial a route of the category and direction to which it belongs, and prohibits dialing routes of other categories and directions until the dialing group is completely released: PP, OP train anti-repeat relays; MP shunting anti-repeat relays.

The relays listed above determine the traffic light that allows movement along the dialed route, i.e. the beginning of the route: VKM auxiliary final shunting, determines the traffic light to which or behind which the shunting route is dialed, i.e. the end of the route; PU and MU plus and minus control relays for switching on the starting circuits for switching arrows along the dialed route.

The complete scheme of the dial-up group is made up of four chains of interconnections:

1 switching on the KN relay,

2 turn on the AKN relay,

3 relay PU and MU,

4 correspondence diagram with the inclusion of the initial relays of train and shunting routes.

The KN and NKN relays are installed in the set-up blocks that control traffic lights and turn on when the corresponding buttons on the control panel are pressed.

The NPM block contains a push-button relay NKN, which is switched on when the train button is pressed, and a relay KN, which is activated when a shunting route is set.

Push-button relays of the NM block I are switched on through an additional push-button relay K of the NM block I E. If the button of this block is pressed first, then the THM rear bus has power to the P pole, and the NKN relay is turned on. If the route is set before this traffic light and the button is the final one, then there is no power on the TNM bus, but there is power on the HM bus, which leads to the activation of the KN relay.